Internal Gages

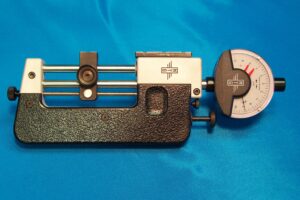

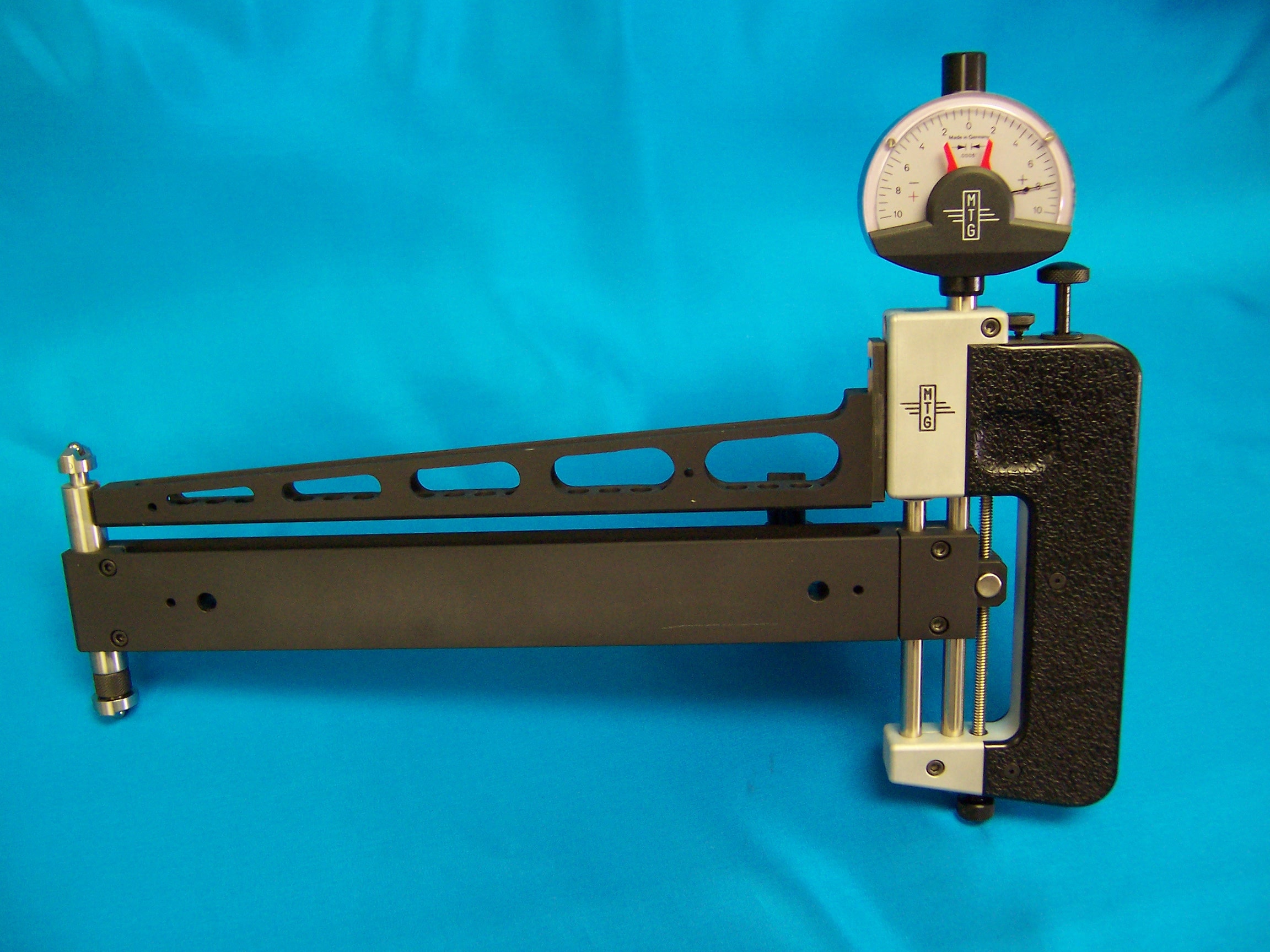

Internal Gage Frames

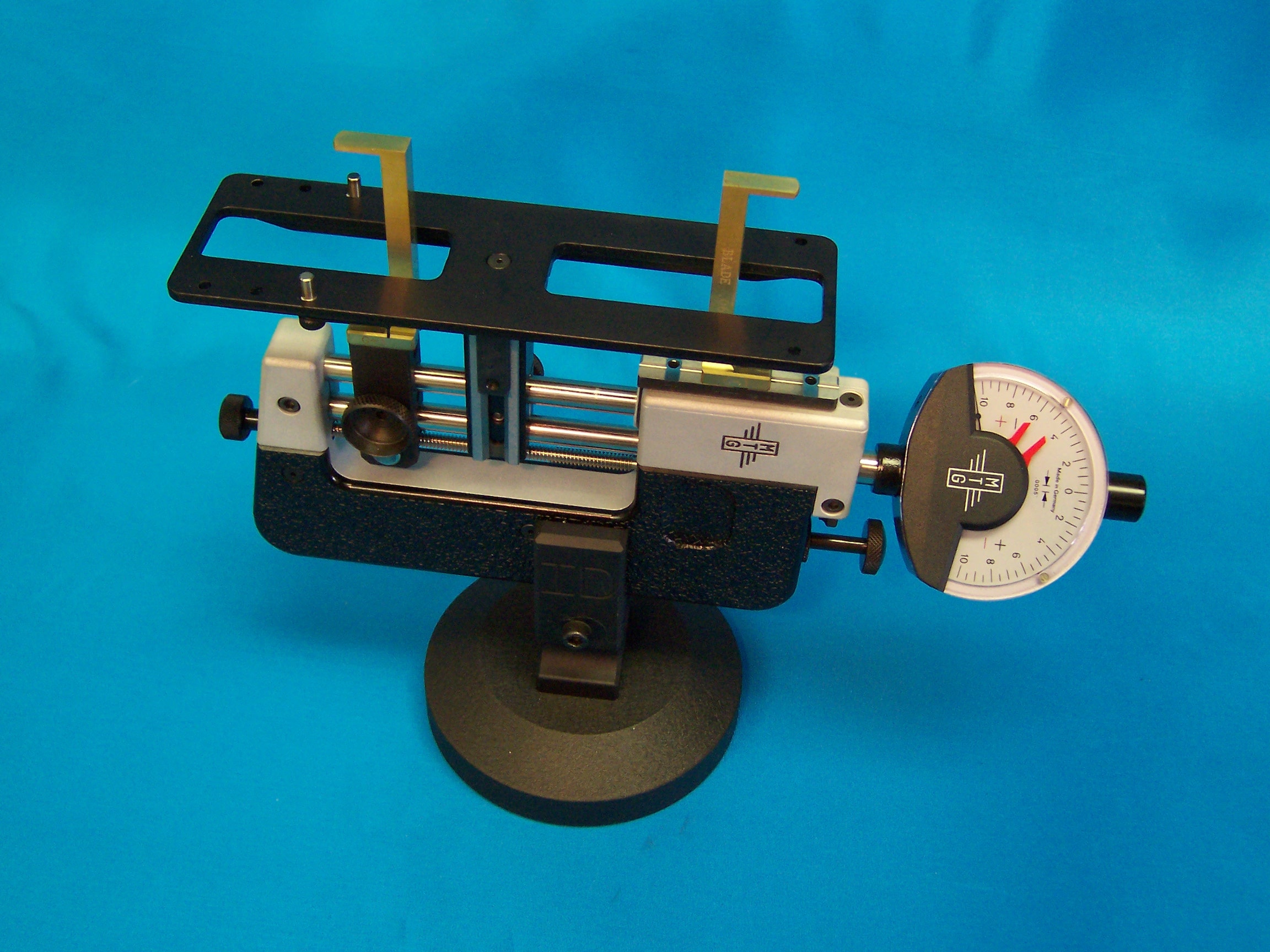

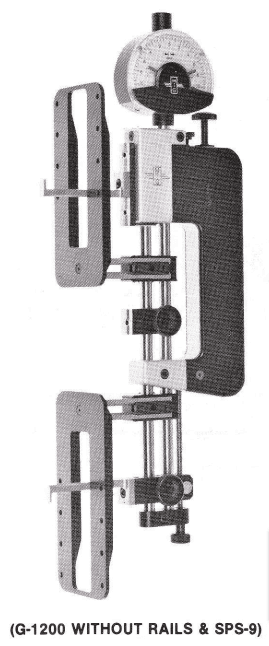

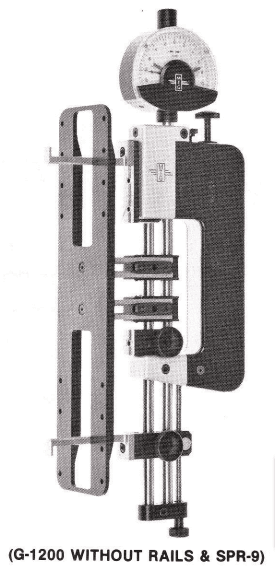

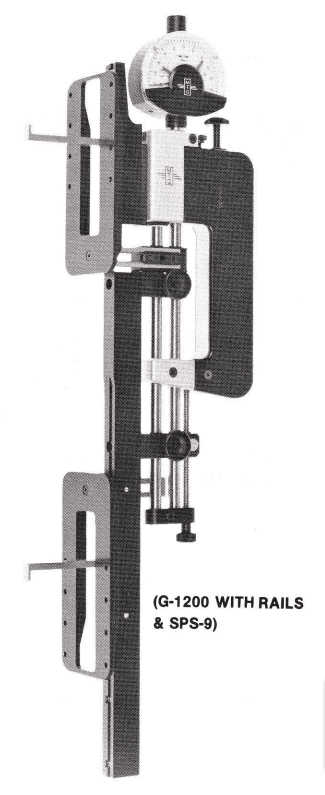

The basic internal gage frames are available in two models. The G-600 with a capacity from .190 inches to 4.5 inches basic and the G-1200 with a capacity from 6 inches to 18 inches. The gage frames are extremely accurate, .000050 inch repeatability is guaranteed. The system was designed to take the abuse of shop use although it is precise enough for the requirements of the quality control or metrology laboratory. Two extension kits are available. The G-600X increases the capacity of the G-600 frame to 5.5 inches basic and the G-1200X increases the capacity of the G-1200 frame to 24 inches basic. The gaging pressure of both internal frames can be adjusted by the operator thereby allowing very “thin wall” parts to be measured, minimizing destortion !

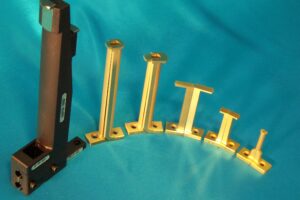

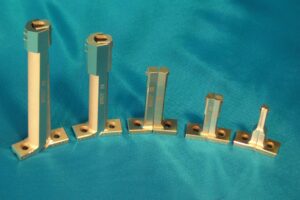

Internal Gage Fingers

MTG offers more sizes, types, and reaches of internal fingers than any other gage manufacturer. Fingers can be manufactured to measure most thread forms including Unified, Buttress, Acme, Stub Acme, Metric, Whitworth, Lowenherz, Ball, 40 Degree Worm, Aero, and Square. Additional geometries are available for bearing races, grooves, bores, tapered bores, gears, splines, and dovetails. Six different lengths are available.

| FINGER PREFIX | OAL LENGTH OF FINGER | MINIMUM / MAXIMUM DIAMETER |

|---|---|---|

| 1.5U | Basic Length 1.25 Inches | Under 5/8 In. Diameter |

| 1.5 | Basic Length 1.5 lnches | 5/8 In. Diameter & Over |

| 2.25 | Basic Length 2.25 Inches | 3/4 In. Diameter & Over |

| 3.0 | Basic Length 3.25 Inches | 1.0 In. Diameter & Over |

| 4.0 | Basic Length 4.12 Inches | 1.0 In. Diameter & Over |

| 5.0 | Basic Length 5.0 Inches | l.5 In. Diameter & Over |

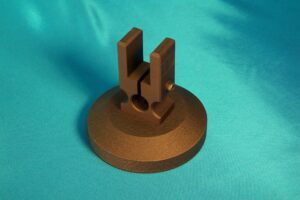

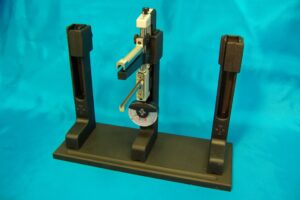

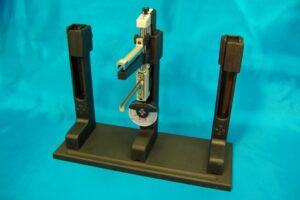

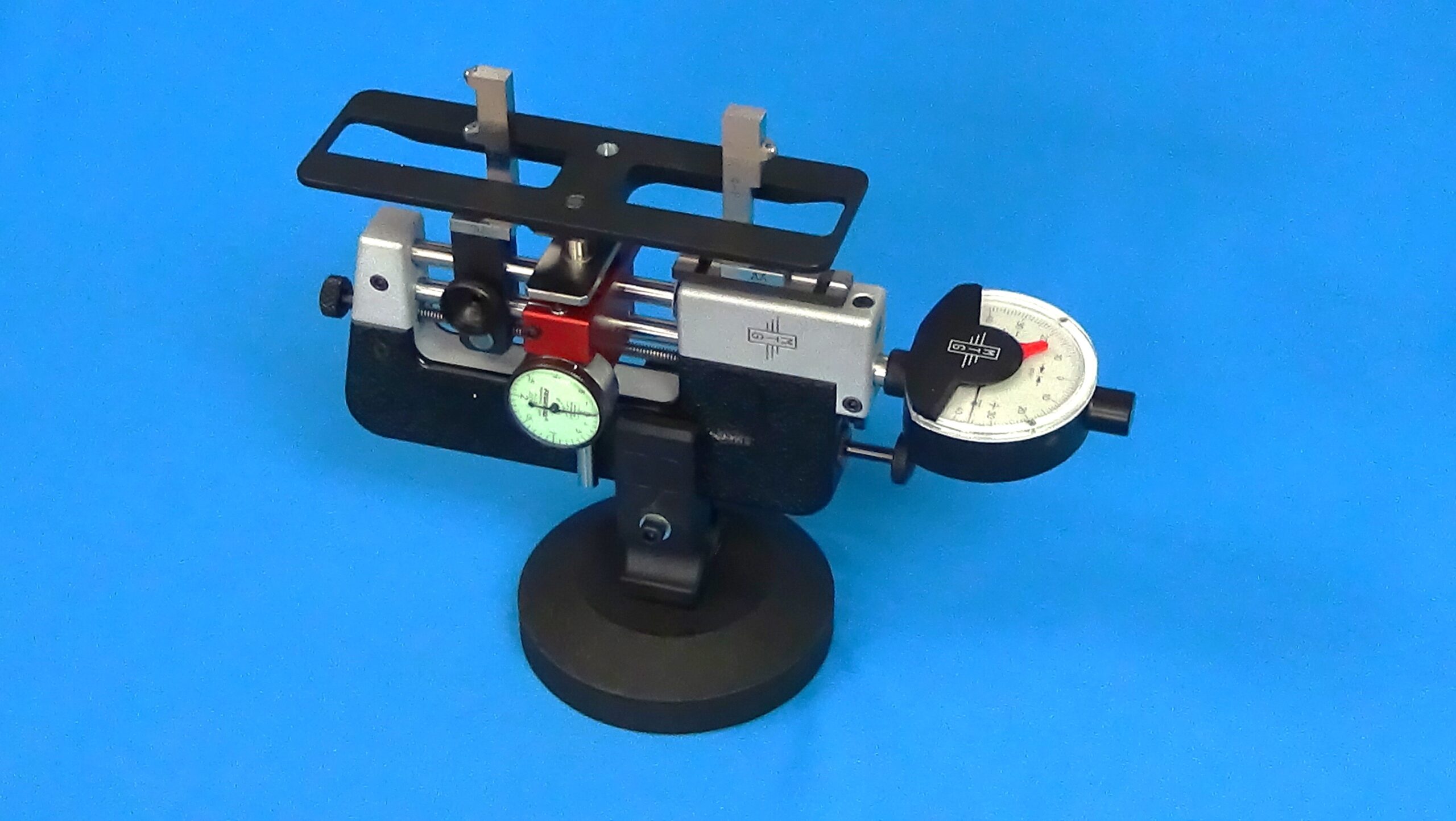

Internal Gage Stands

MTG offers simplicity in measurement. Many times it is necessary for the user to measure more than one element of a thread. Shown below (pictured in red) is an Internal System for thread measurement. The first gage is set up to measure the pitch diameter, the second gage measures the diametrical equivalent of the form (single thread), and the third measures functional diameter. The gage stand shown (three risers) is a GS-3. Two risers is a GS-2. One riser is a GS-1. The GS-1 is expandable to either a GS-2 or GS-3 simply by purchasing additional risers because all three risers share a common base. A round base (GS-O) stand is used to hold the gage frame when measuring grooves and bores of a light weight part with a squaring plate installed. (SEE INTERNAL BORES AND GROOVES BELOW)

Deep Hole Diameters

The MTG Telescoping Tube System (TST) is far more accurate than its competitors who use long segments that bend and deflect. The system can be used on either the G-600 or G-1200 internal gage frames. The reason for its accuracy is the fact that it creates a “Linear” measurement. The TST System uses TST inserts which are available in all the geometries listed for the internal fingers. Diameters as large as 36 inches or more may be measured. There are three standard lengths available, 5 inch reach, 8 inch reach, and 10 inch reach.

Internal Bores And Grooves

Only with the MTG System can a bore diameter, internal groove diameter, and their concentricity to each other be measured with a single gage. This capability is due to the “MTG SQUARING PLATE” accessory. Four different squaring plates are available. All plates are slotted through their centers permitting the use of all our internal fingers.

Squaring plate arms are adjustable for length so the reach of the fingers into any bore can be set to the desired dimension.

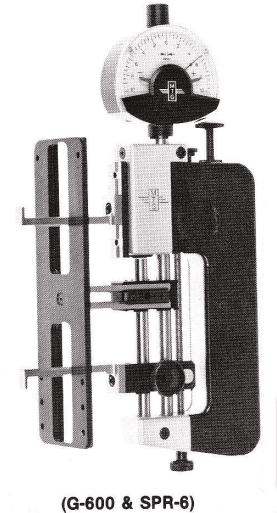

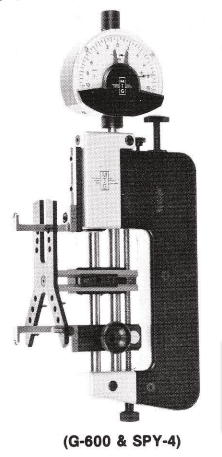

Sample Squaring Plate Gage Frame Assemblies

Versatile Squaring Plates

The Y-shaped squaring plate shown on these pages will handle bores up to 4 in. dia. Rectangular plates 6 and 9 in. long are also available. A split rectangular model is 9 in. long but can be expanded to 18 in.

All plates are slotted through their centers to permit various finger settings, and all have multiple locations for eccentric pins.

Squaring plate arms are adjustable for length, so the reach of the fingers into the bore can be set to any dimension.

| Part Numbers for Squaring Plates | ||

|---|---|---|

| Type | Length, In. | Part No. |

| Y-Shape | 4 | SPY-4 |

| Rectangular | 6 | SPR-6 |

| Rectangular | 9 | SPR-9 |

| Split Rectangular | 9 | SPS-9 |

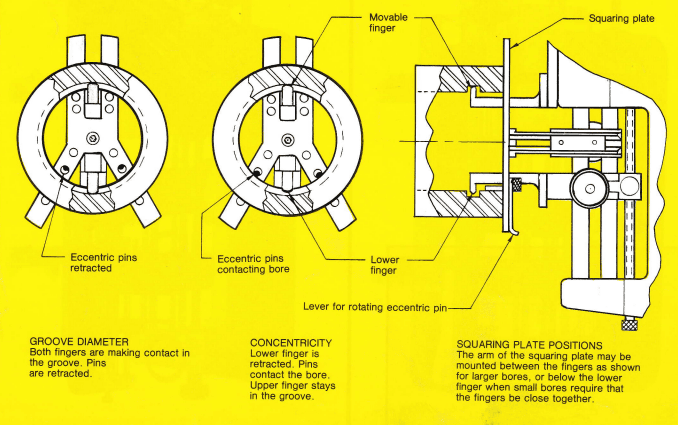

Bore & Groove Inspection

CHECKING THE BORE

Banking the workpiece against the squaring plate keeps the workpiece straight, so it is necessary to rock it in only one plane to find the high point of the diameter. The squaring plate may be moved in or out to permit gaging at any depth.

CHECKING THE GROOVE

After bores have been inspected for diameter, the gage is quickly reset to groove diameter and the squaring plate moved to a point that sets the fingers for groove location. Next, reset the indicator, then proceed with gaging.

CHECKING CONCENTRICITY

With the gage still set for groove diameter, rotate two eccentric pins mounted in the squaring plate. Slide the plate until the pins bear down against the bore, taking the stationary finger out of contact with the groove. Since the upper finger is now reading the groove while the eccentric pins are contacting the bore, rotation of the workpiece will cause the indicator to show any runout between the two diameters.

Anti-deflection Braces

Anti-deflection braces are recommended when using .000050 graduation mechanical indicators, electronic heads or where an error might be suspected because of the awkwardness of accessibility involved when measuring the part. Anti-deflection braces are available in 5 different lengths for internal fingers only. They are not necessary when using the TST System.

Tapered Internal Threads

MTG now enables the operator or quality control inspector to accurately measure internal tapered threads. No tapered set masters are required. Simple L1 location setting is designed into the system. The system can be hand-held or stand mounted. Fingers are available to measure pitch diameter, functional diameter, minor diameter, included angle, and full form (single thread) on 60 degree tapered threads.